APPLICATIONS

Asso Werke has been producing high performance thermal components for two or four stroke engines for 70 years.

Asso Werke customers are the most important manufacturers of high-performance vehicles all over the world.

PRODUCTS

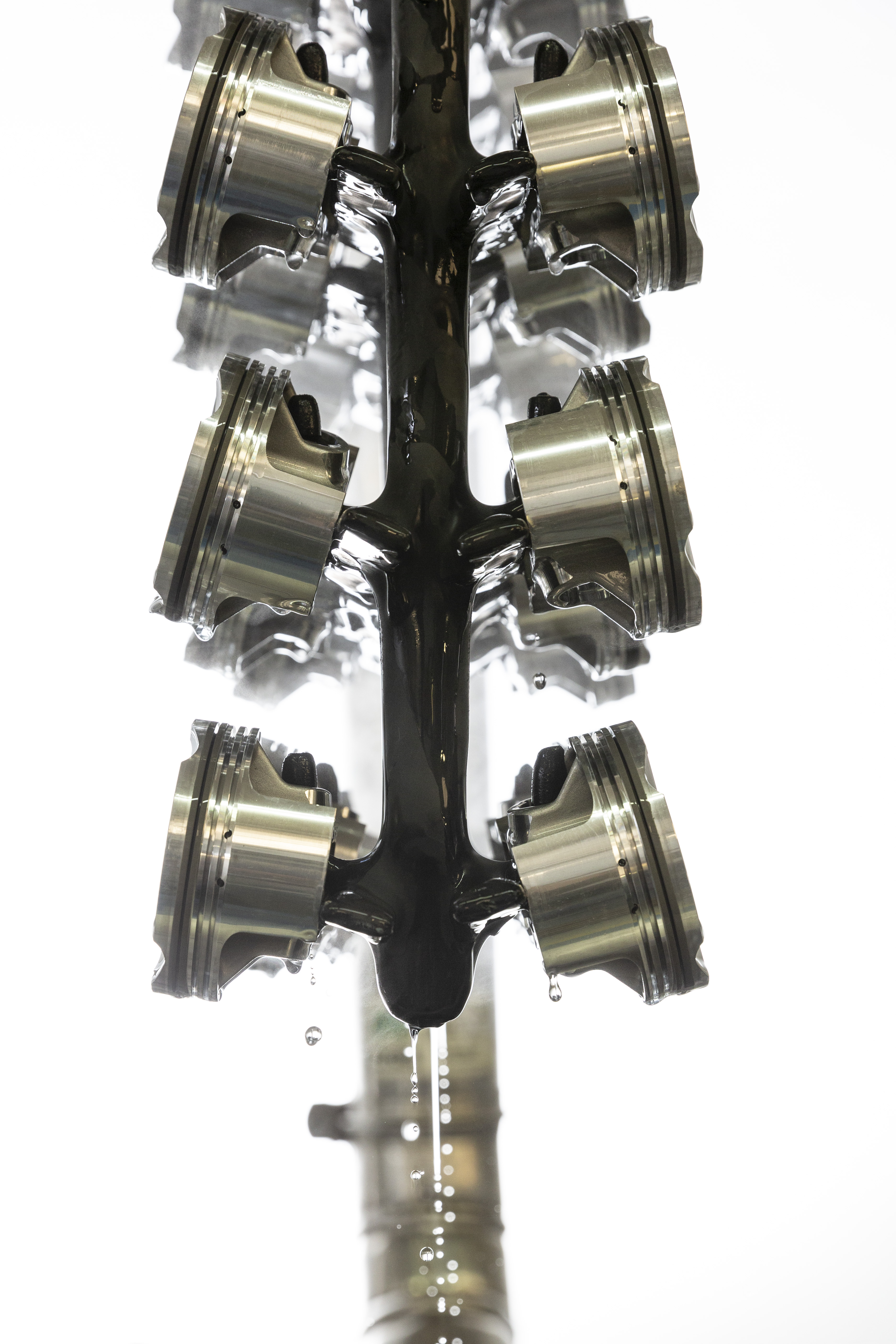

Pistons

Asso Werke is able to recommend the most innovative solutions in terms of technical characteristics, starting from the expected performance of the most powerful engines.

Each piston is the result of a project tailored to meet the high requirements of demanding customers.

TECHNICAL DETAILS

Diameter

- Range 18-200 mm

Material

- Aluminium alloys also with box in box structure

Technology

- Gravity Die Casting

- Forge

- Box Bridge Design (double ribbed)

Treatment

- Low and high thickness anodizing treatment

Coating

- Tin plating

- Serigraphic coating on the skirt (molybdenum disulphide)

- DLC coating

- Thermal barrier with ceramic coating

THE RIGHT SOLUTION FOR EVERY REQUEST

CYLINDERS OR LINERS WITH PISTONS FOR MAXIMUM PERFORMANCES

Cylinders and Liners

The joint design and engineering of pistons with cylinders or liners, for 2 or 4 stroke engines, guarantees the achievement of maximum performances. Thanks to unique technical characteristics and specific surface treatments they ensure a unique reliability.

CYLINDERS

Diameter

- Range 70-120 mm

Material

- Aluminum Alloys

Technology

- Gravity Die Casting

- HPDC-High Pressure Die Casting

Internal Coating

- Nickel and Silicon Carbide

- Plasma

LINERS

Diameter

- Range 40-120 mm

Material

- Alloys

- Steel

- Cast iron

Technology

- Gravity Die Casting

- Forge

- Cofused in aluminium cylinders

Internal Coating

- Nickel and Silicon Carbide

- Plasma

Piston Rings

Asso Werke developed a unique and patented material for Piston Rings offering the best combination of sealing, oil consumption and blow-by control.

TECHNICAL DETAILS

Material

- Various types of Cast Irons

- Steel piston rings, with different surface treatments

- Special patented Cast Iron alloys

Diameter

- Range 18-160 mm

Thickness

- Range 0,55 – 2 mm and over

Treatment

- Patented Heat Treatment

- Vacuum Nitriding Process

Coating

- Chrome Plating

- Chrome Nitriding Coating

- DLC (Diamond-Like Carbon)

- Other PVD coatings

ONLY THREE MAJOR PISTON RING MANUFACTURERS IN THE WORLD

A SMALL BUT CRITICAL COMPONENT

Gudgeon Pins

Asso Werke developed a special material with the most reliable heat and surface treatments.

TECHNICAL DETAILS

Diameter

- Range 8-50 mm

Material

- Various Steel grades

- Advanced aerospace steel grade with high micro-purity remelts

Shape of internal bore

- Cylindrical

- Double tapered

- Multi curvilinear

Heat Treatment

- Case Nitring

- Case Hardening

- Low Pressure Carburizing

- Quenched and tempered treatment

Coating

- DLC (Diamond-Like Carbon)

- Other PVD coatings

Engine Blocks

The machining and surface coating of Engine Blocks represents the natural evolution for a manufacturer of thermal components for high-performance engines.

TECHNICAL DETAILS

Weight

- Up to 30kgs

Cylinders

- V4, V6, V8

Material

- Aluminium alloys, also with cocasted Cast Iron liners

Capabilities

- Machining

- Honing

- Fire deck fine grinding

- Assembly

Coating

- Nickel and Silicon Carbide

- Plasma

NEW PRODUCT LINE: ENGINE BLOCKS

FROM SINGLE COMPONENTS TO ASSEMBLIES

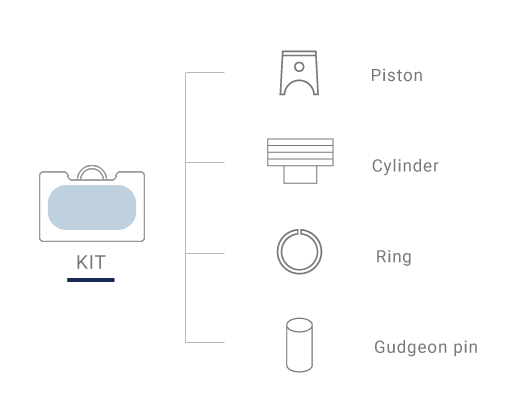

Piston Systems

The supply of internally developed assemblies including Piston, Cylinder, Rings and Gudgeon Pin guarantees optimum performances.